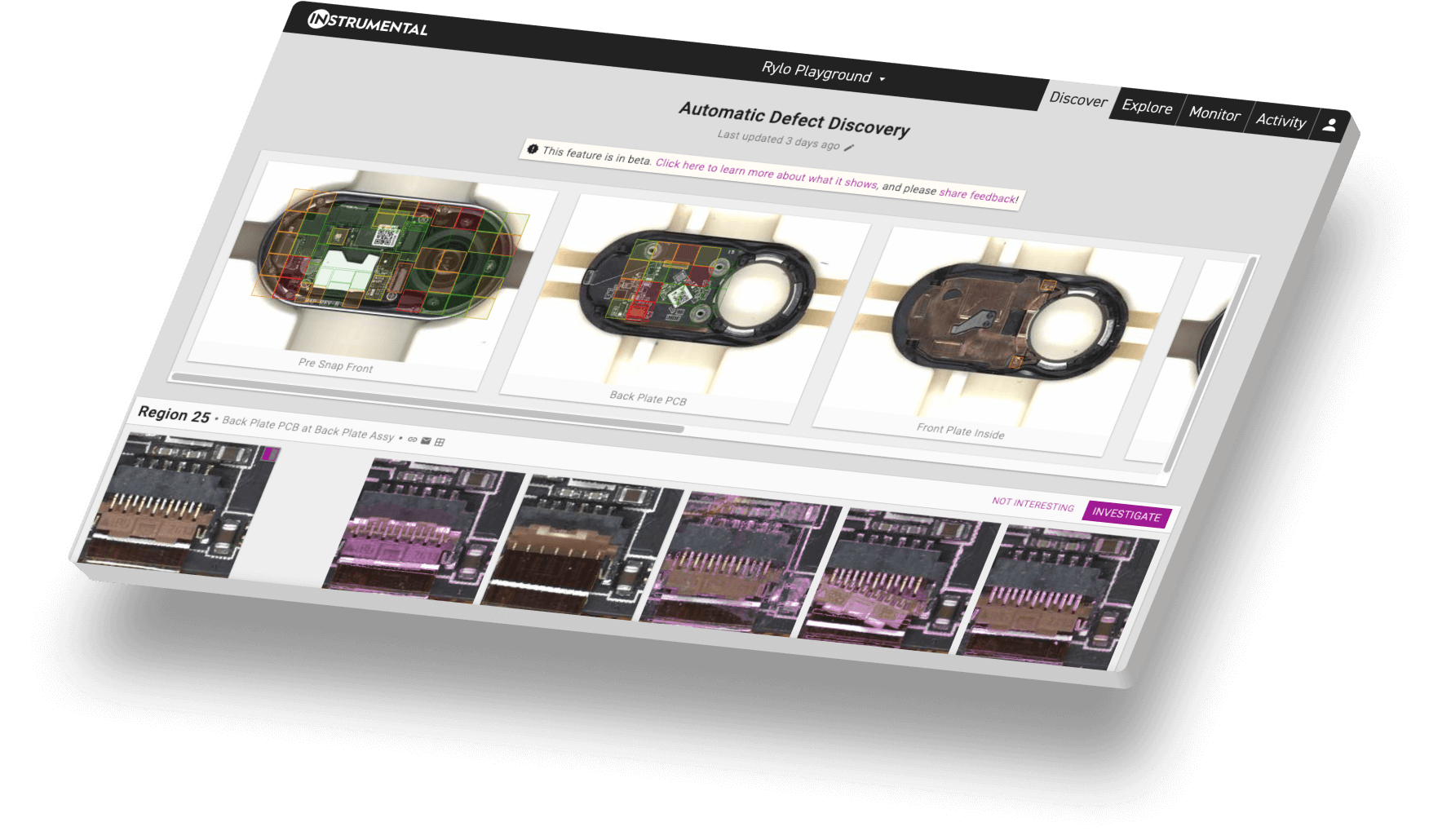

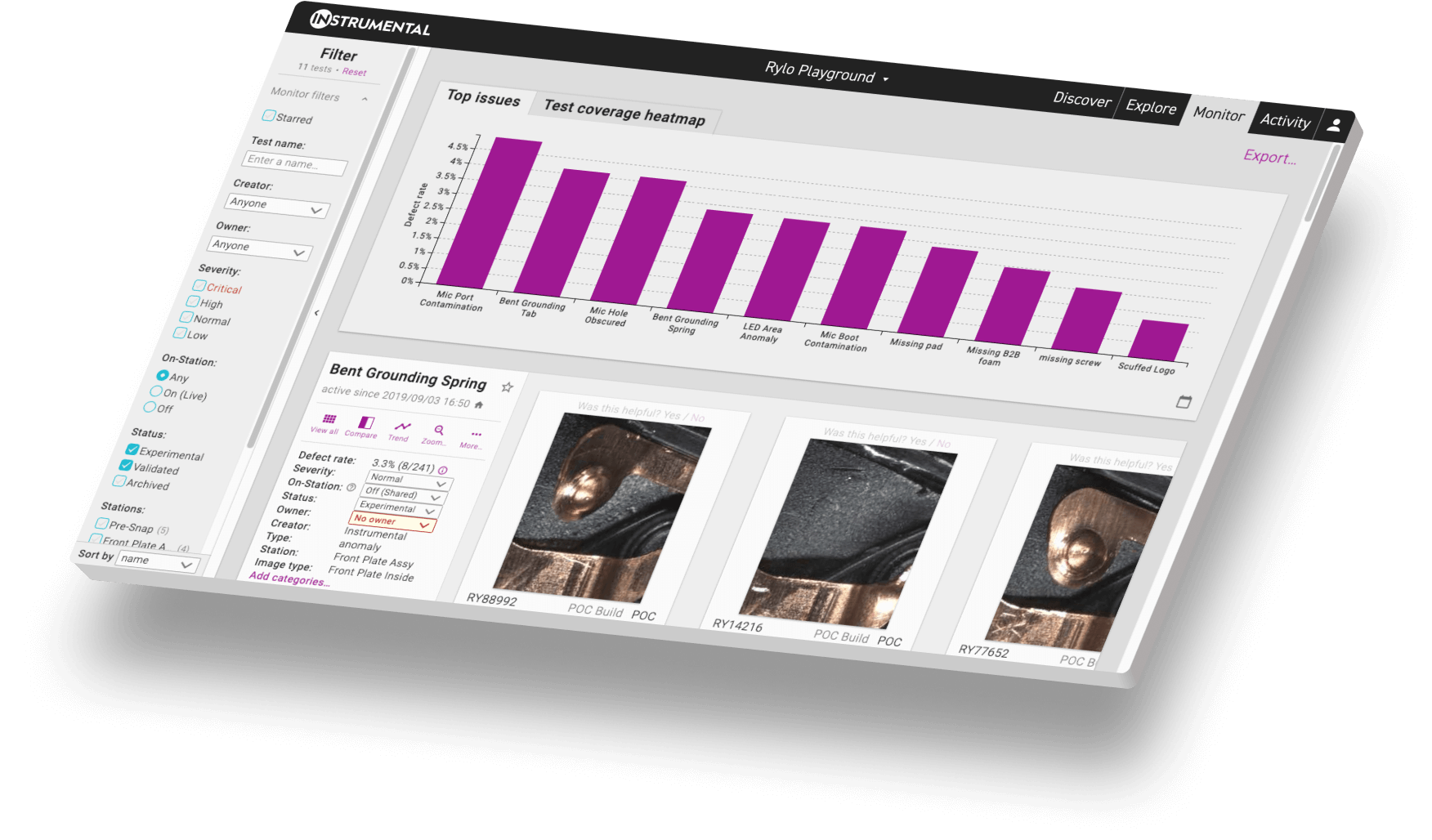

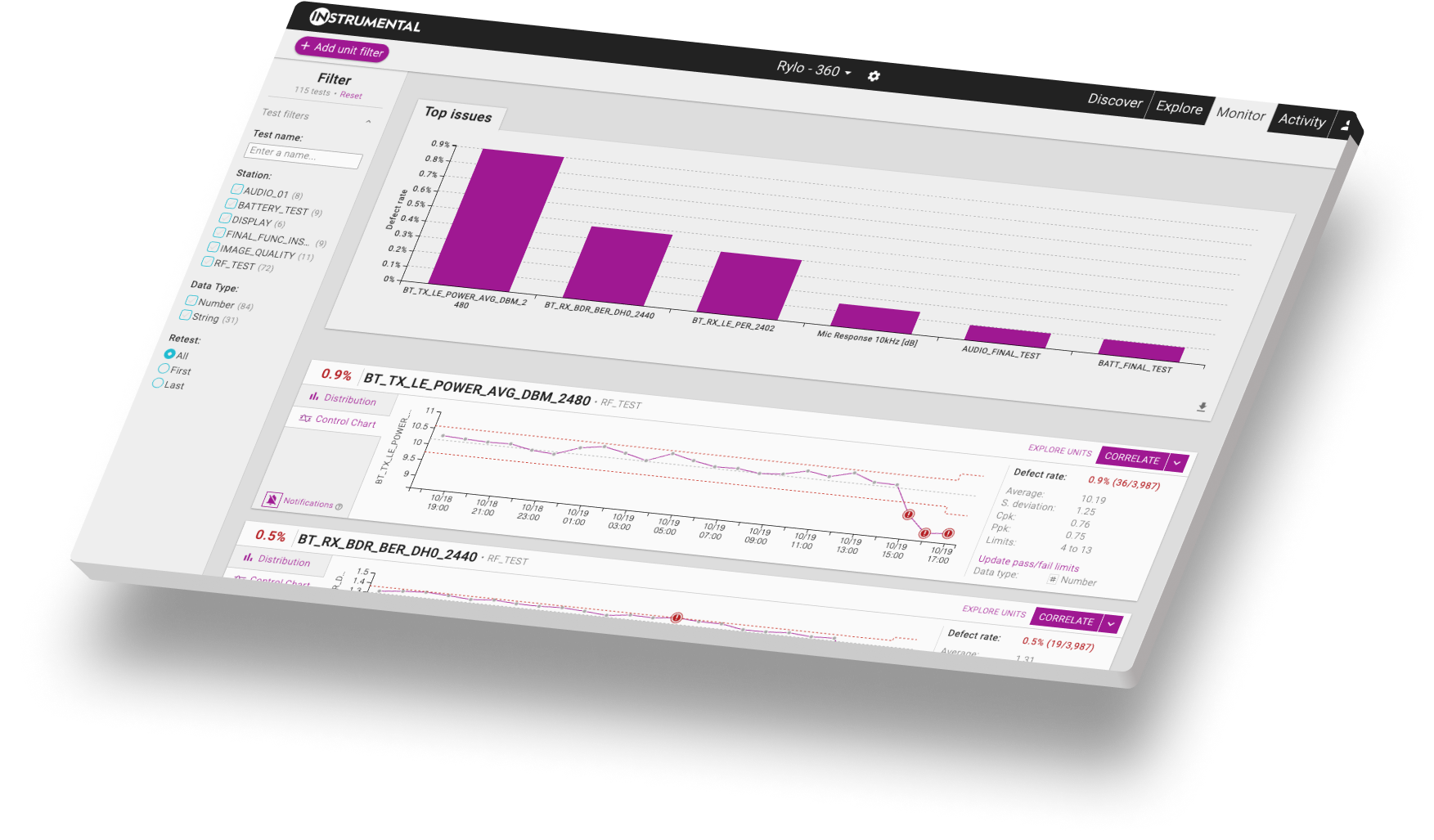

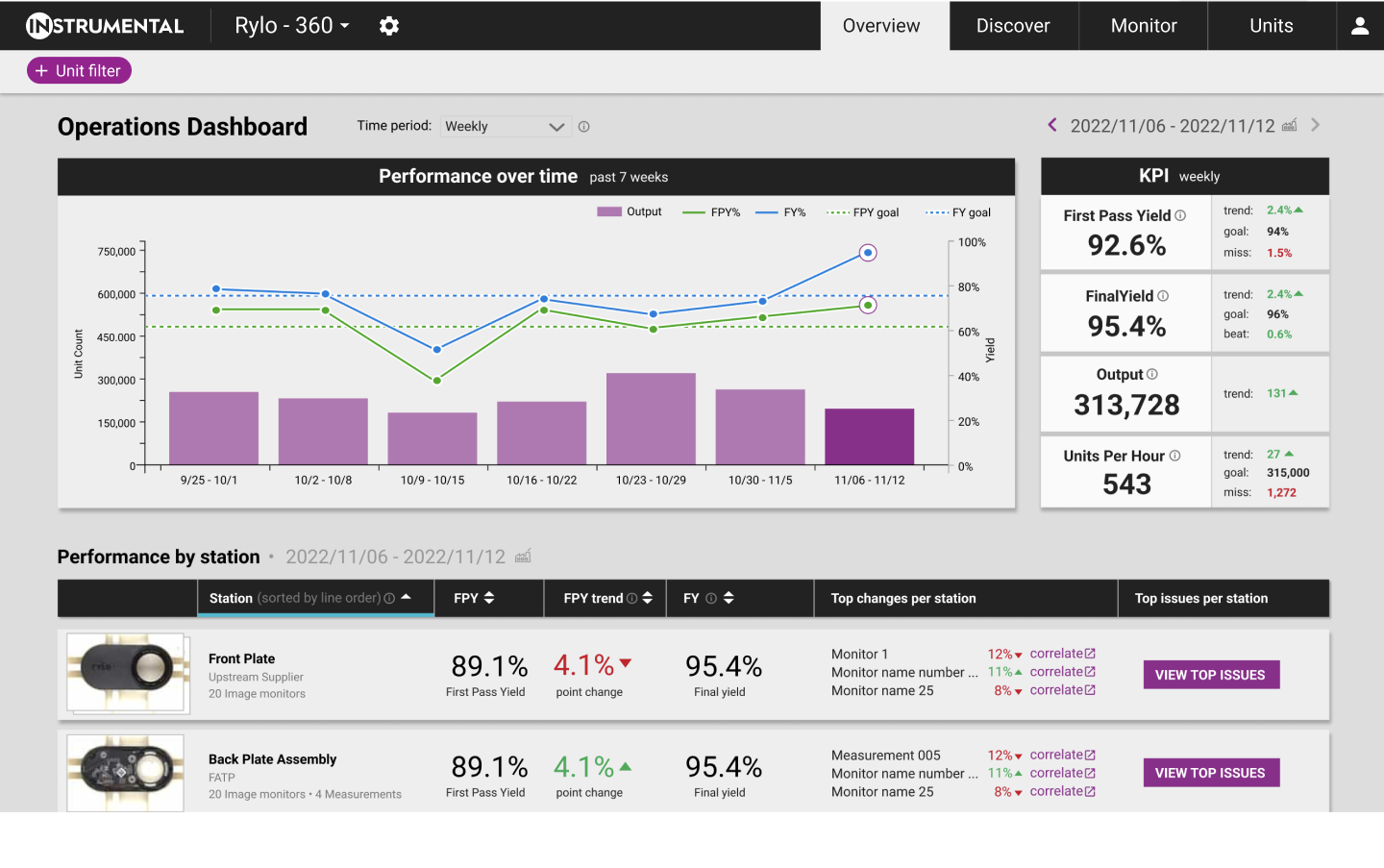

MONITORContinuously improve with confidence

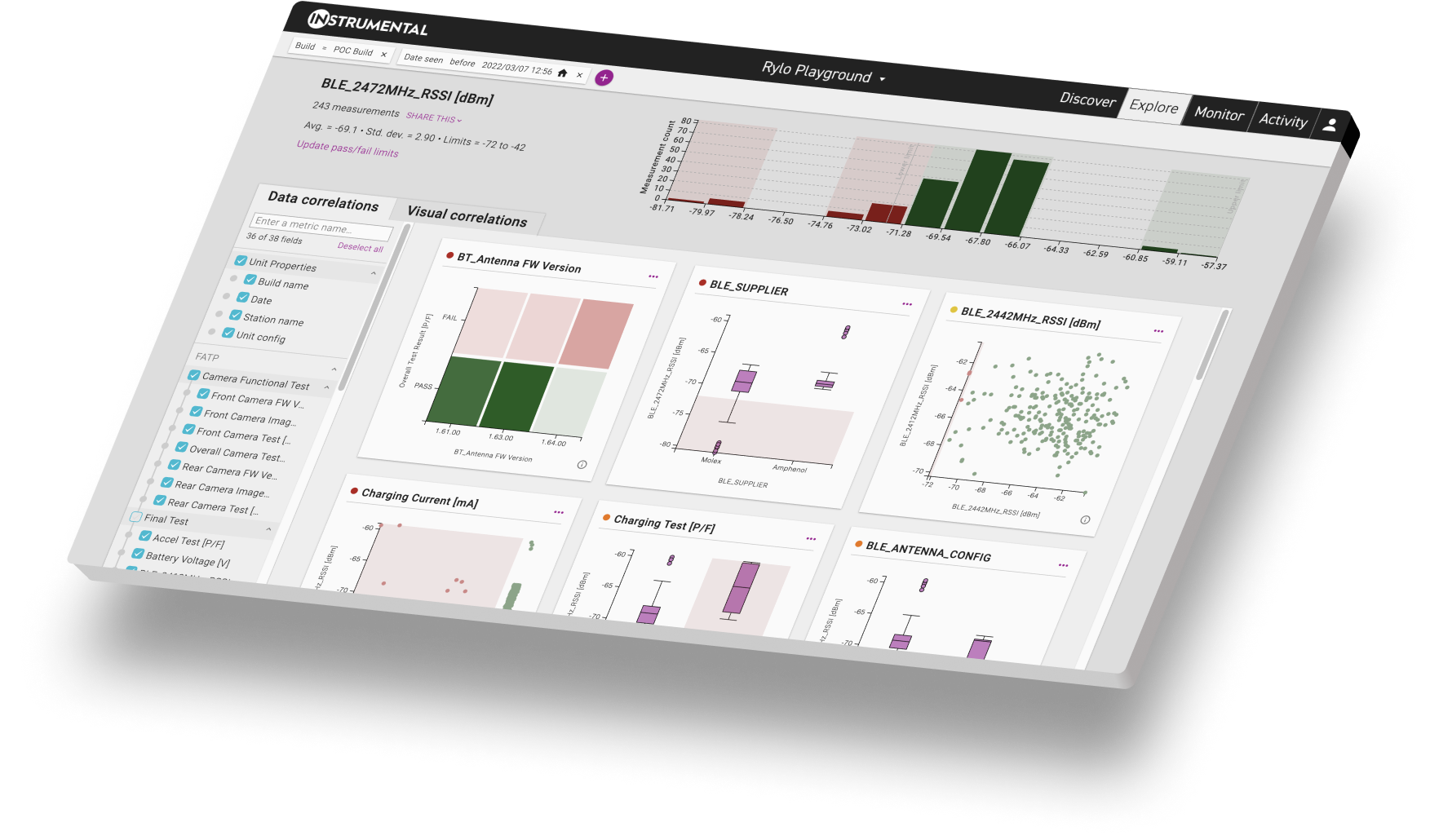

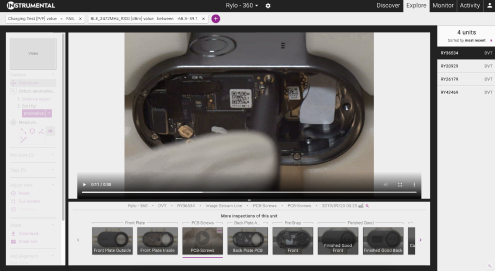

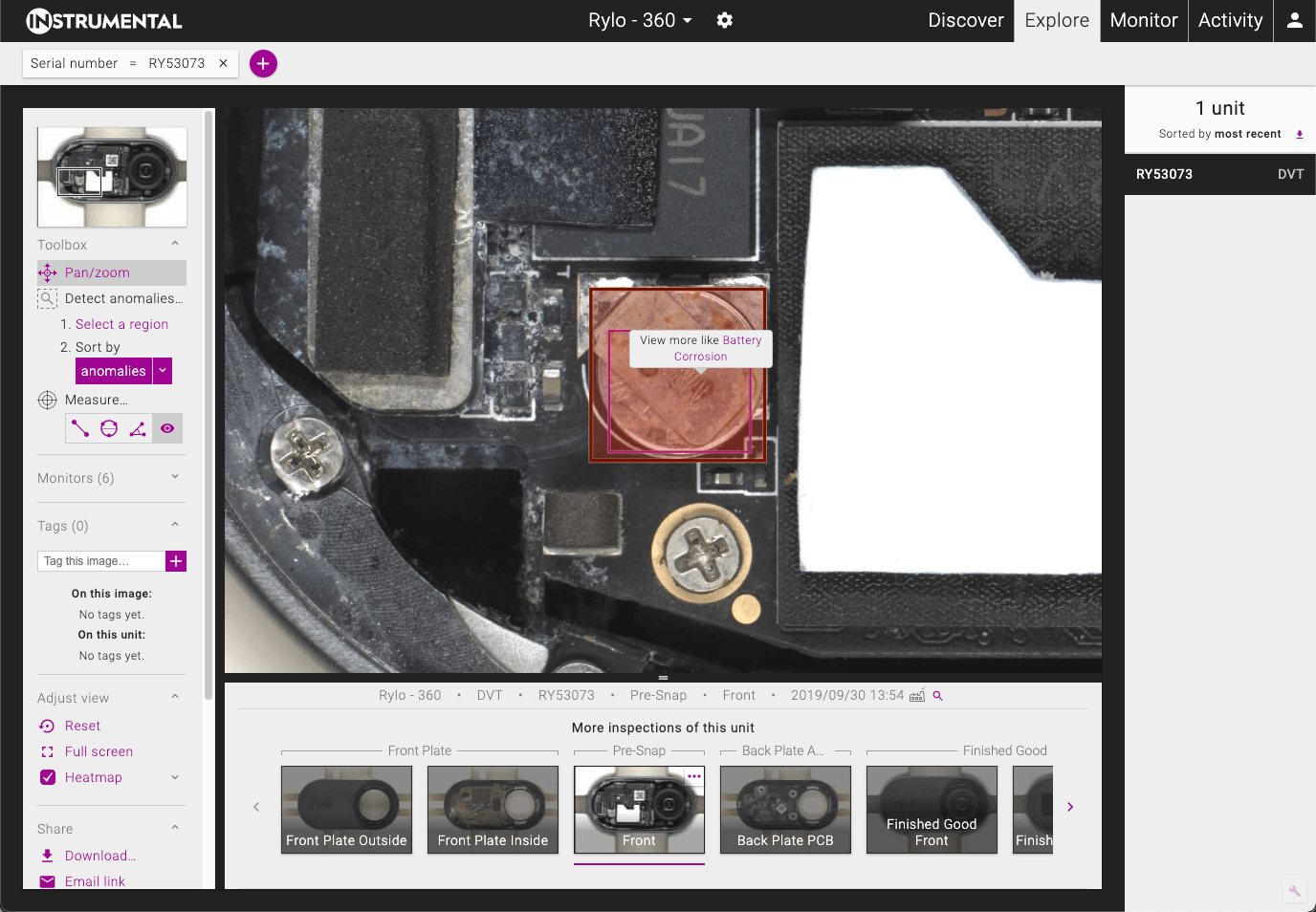

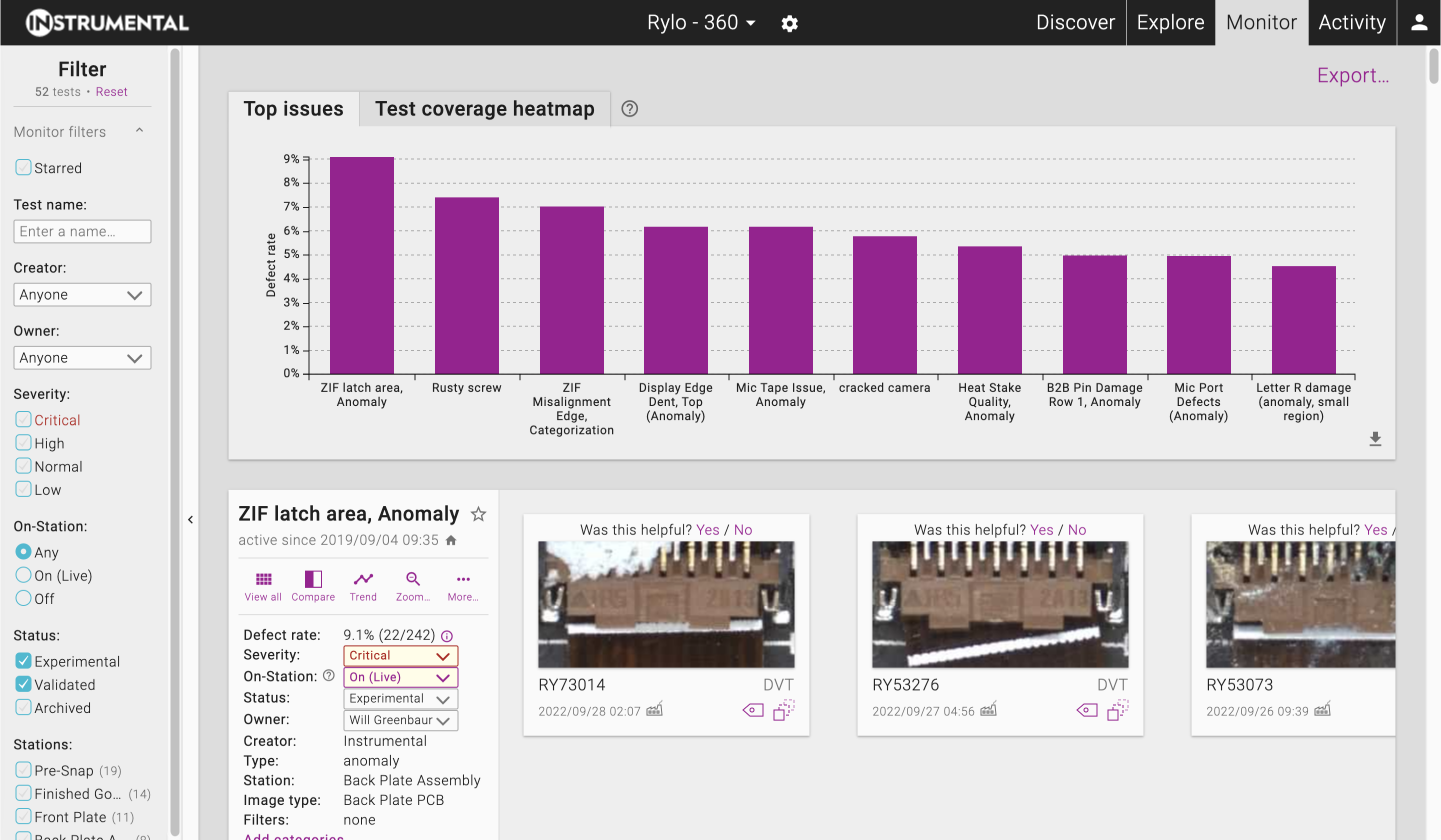

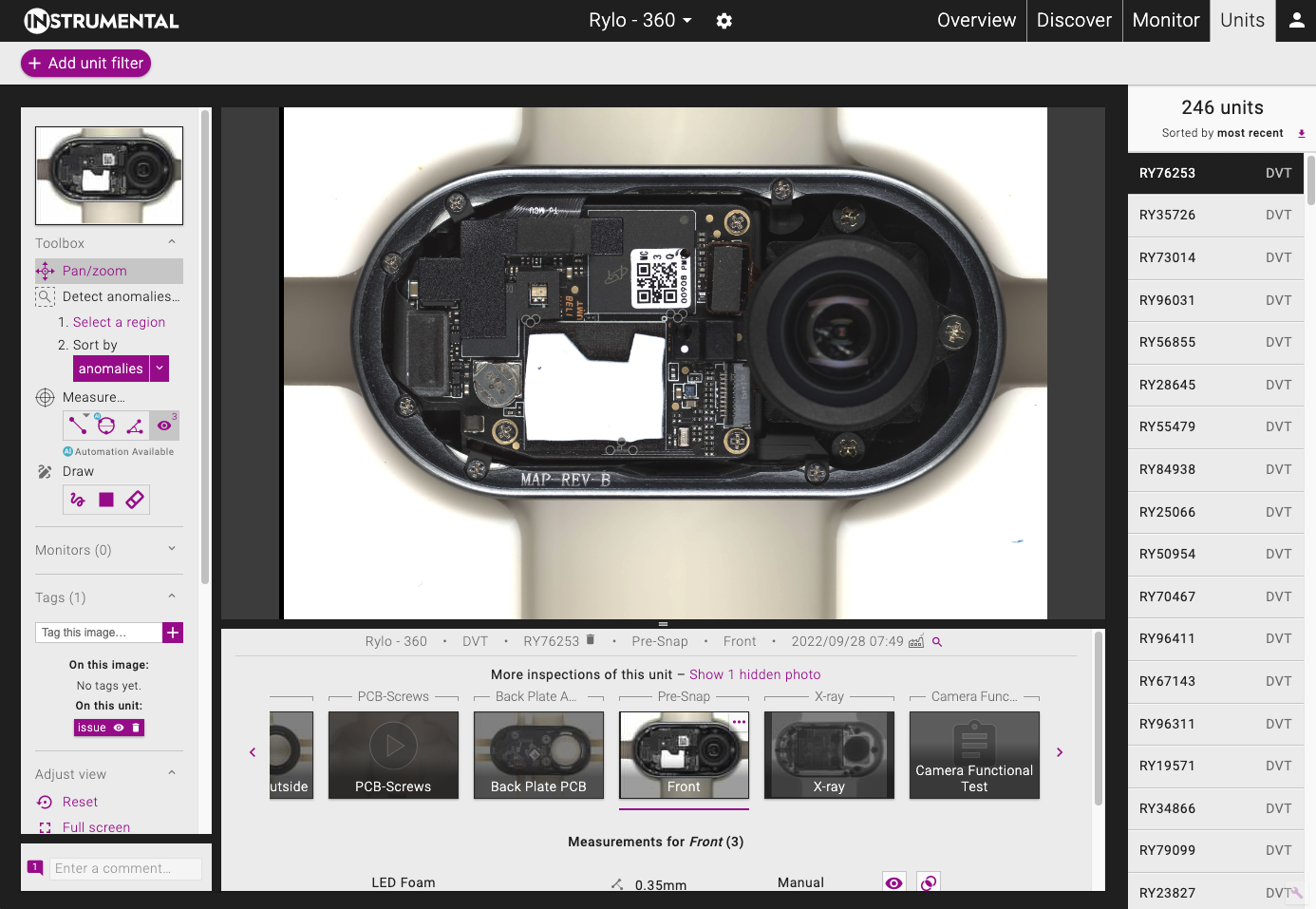

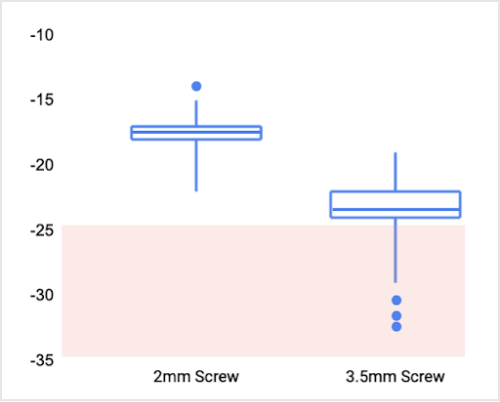

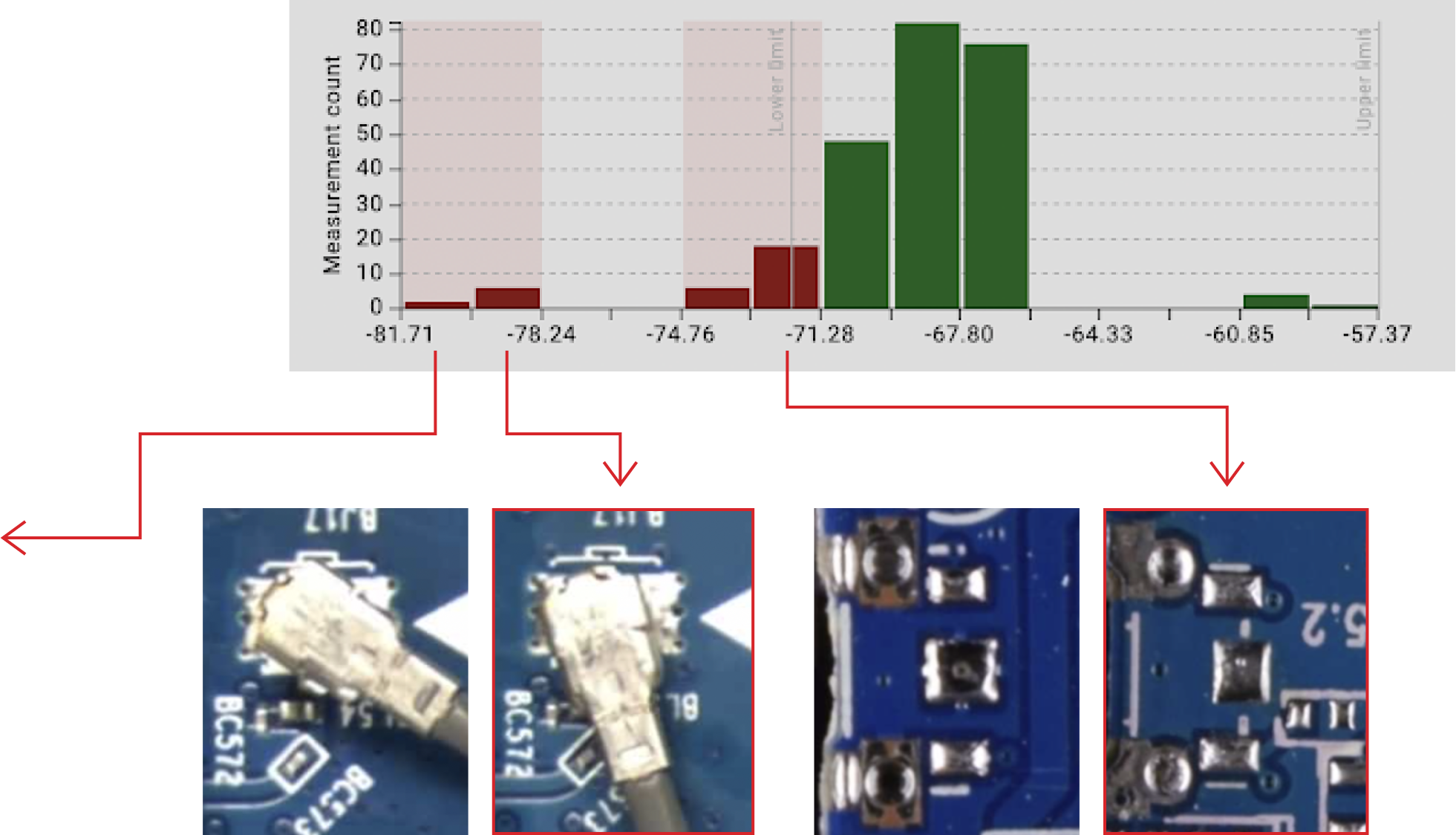

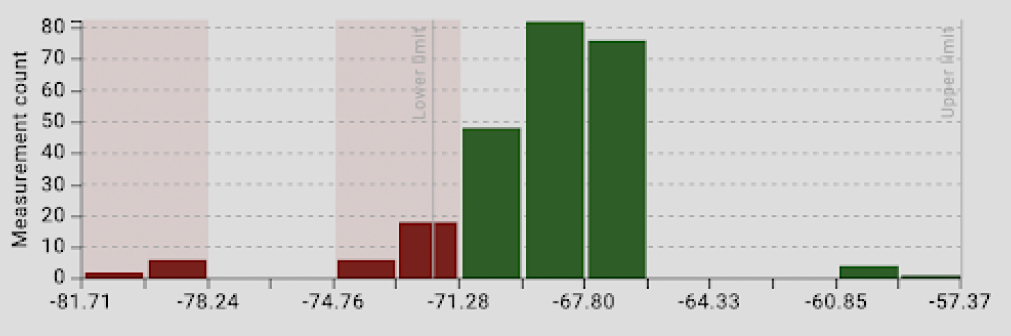

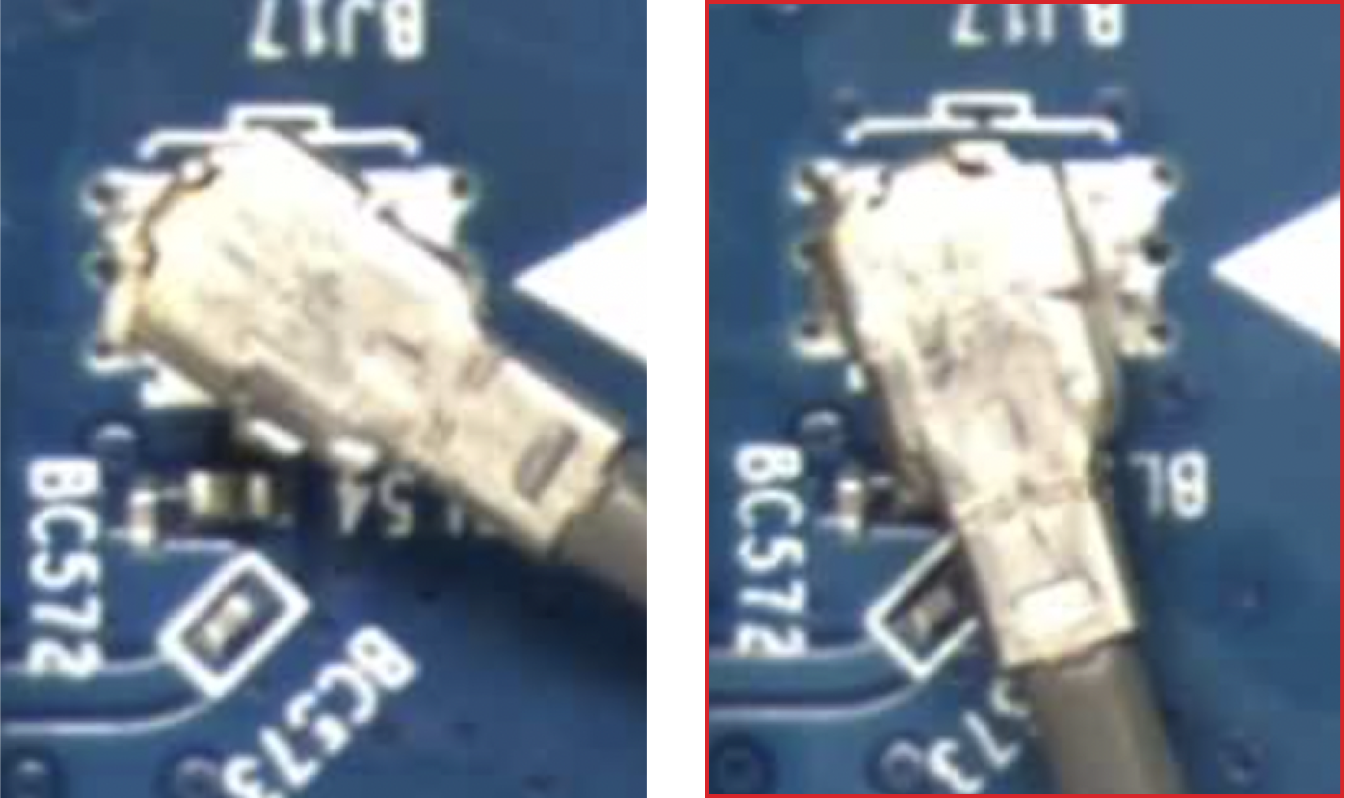

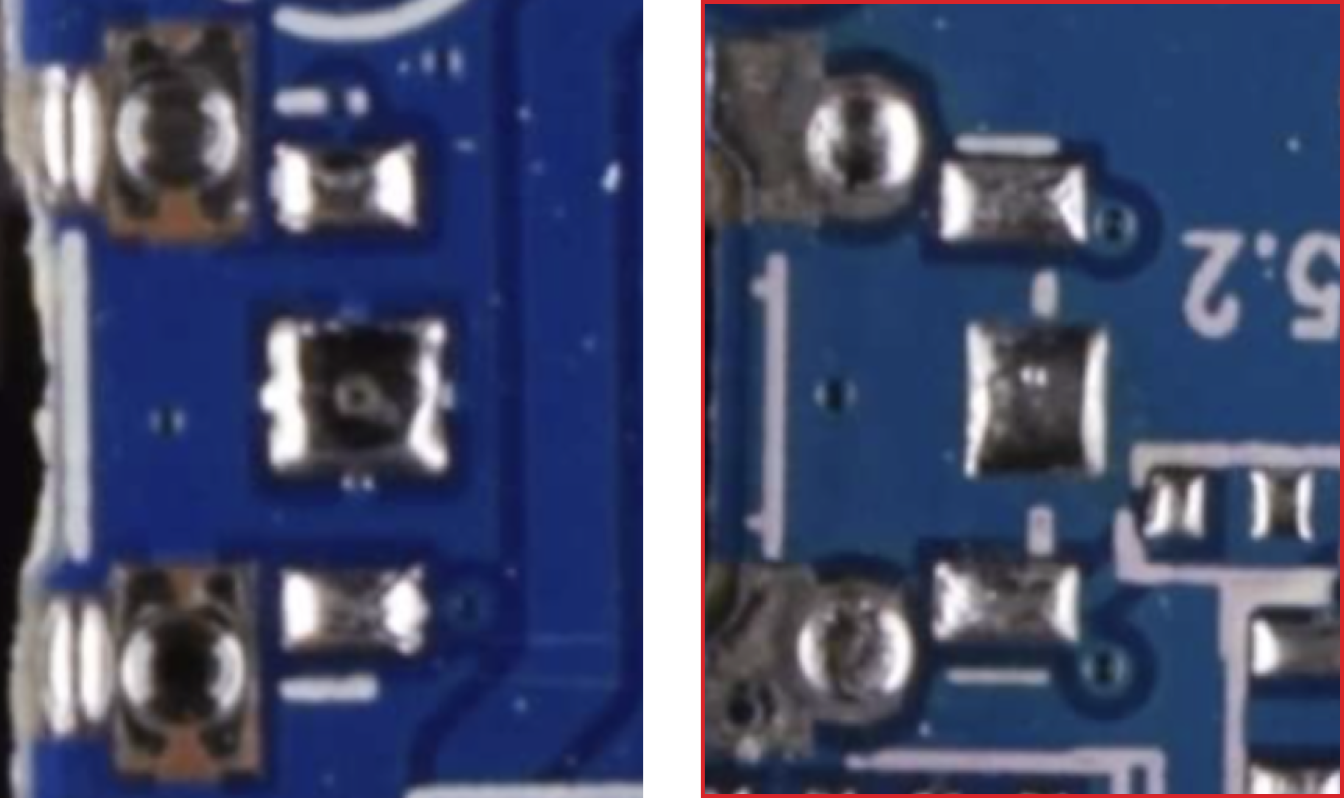

Proactive monitoring ensures issues are caught earlier and don’t lead to missed production targets. With Image Streams, create dozens of tests in minutes by training our AI to understand the difference between passing and failing to solve issues on the line. With Data Streams, view control charts, Cpk, and receive Statistical Process Control (SPC) alerts if tests start to drift.

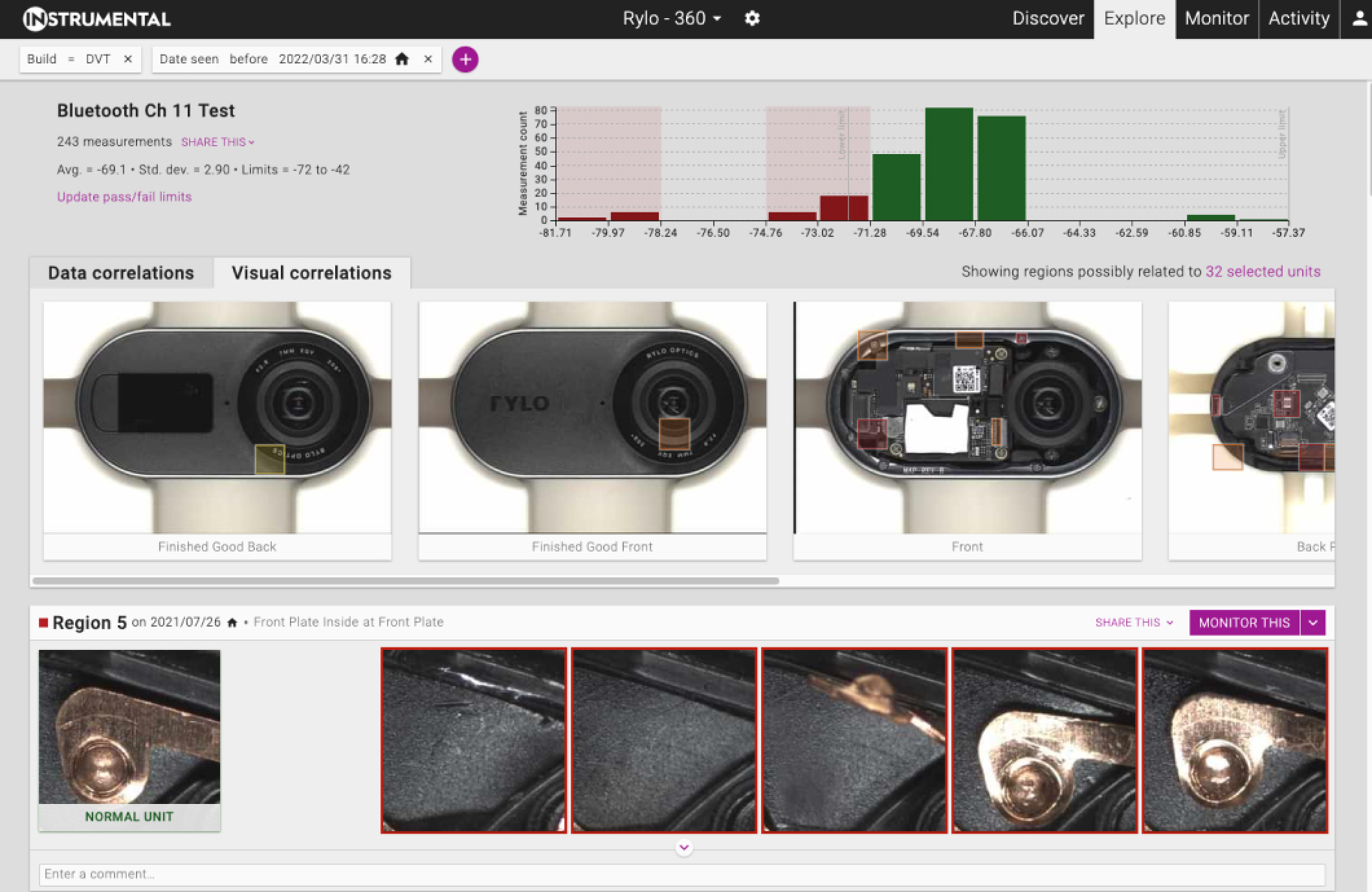

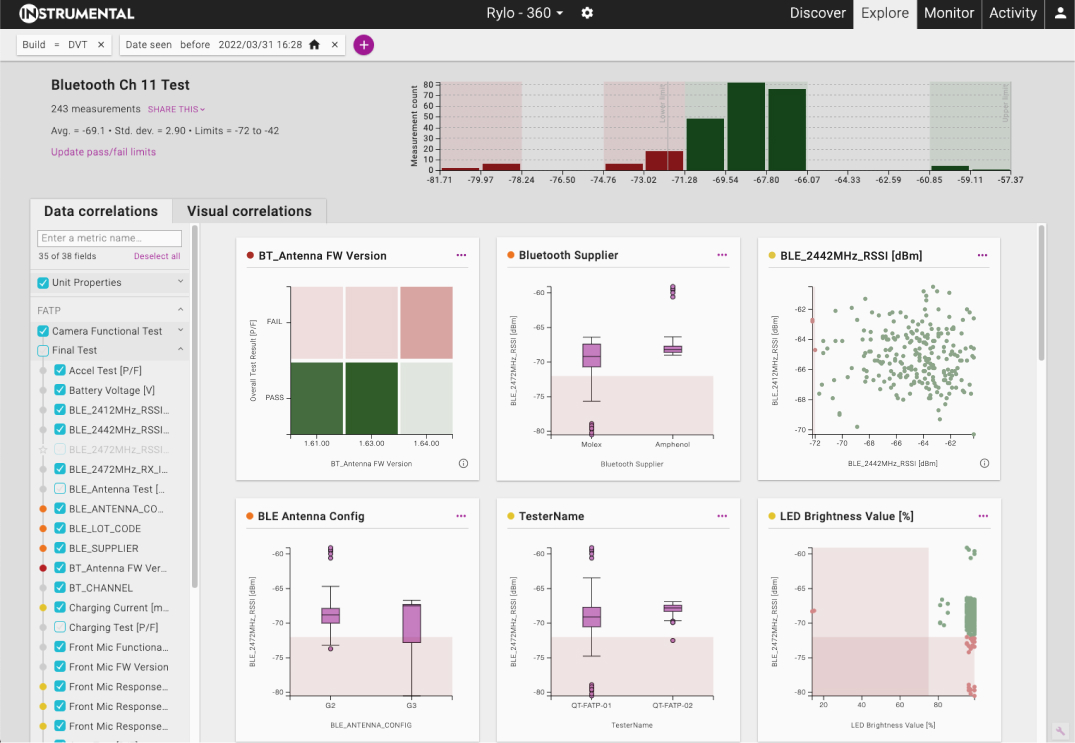

Users can opt to receive personalized alerts for visual anomalies and test data with a few clicks. When issues do occur, quickly find the root cause by diving into our correlations feature.